Resin Bonded Aggregates

Resin Bound and Resin Bonded systems look and perform very differently.

Not sure of the difference between Resin Bound and Resin Bonded? Find out more.

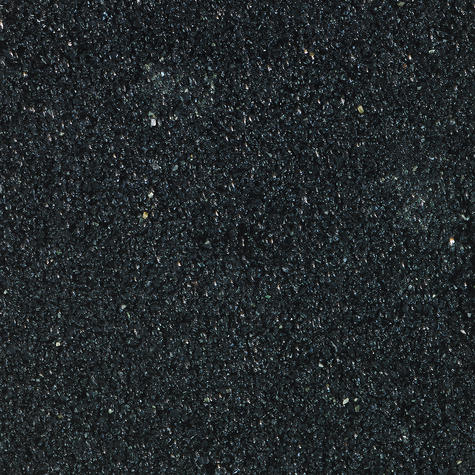

DALTEX Resin Bonded aggregates and gravels offer the ultimate in quality and consistency for Resin Bonded surfaces. Available in a large selection of colours, DALTEX Resin Bonded aggregate is dust free and graded to bond into any resin substrate. All Resin Bonded aggregates are in stock and available for next day delivery.

To download a copy of Resin Bonded Surfacing Advisory notes, click here.

View productsThe difference between Resin Bound and Resin Bonded

Resin Bound system

- The aggregate is mixed in with the resin.

- The resulting material is trowelled onto the surface in an even layer.

- This leaves a smooth, flat finish with no loose gravel.

- This gives a permeable, porous surface which allows water to drain through.

- Resin Bound surfaces give a weed resistant, hard wearing, low maintenance finish.

- This is a SUDS compliant solution.

Resin Bonded system

- The layer of resin is spread across the surface and the aggregate or gravel is scattered into it.

- The majority of the aggregate will adhere to the resin while leaving some loose on the top.

- This is designed to give the appearance of loose gravel.

- Any excessive loose gravel can be removed once the resin is cured.

- This surface is non-porous and is not a SUDS compliant solution.