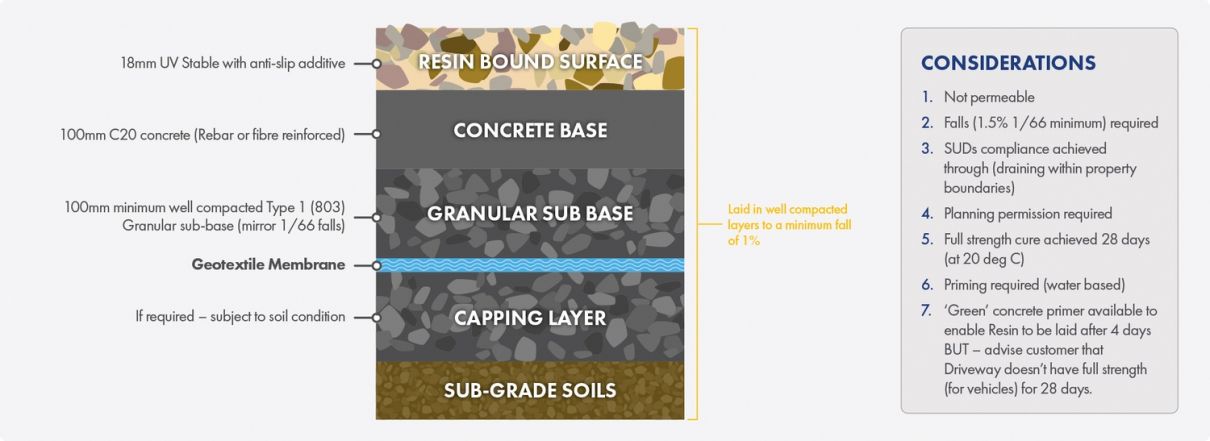

Base Build-up Course - Concrete

Concrete Resin Bound Base Build Up For Domestic Driveways

It is important to understand the base that you are working with before planning your Resin Bound system. This guide is to help you understand the concrete base course.

This base course is non-permeable, meaning additional drainage is required in order to comply with SUDS regulations.

Purpose

The purpose of this base course is to provide an attractive, durable and seamless natural stone or gravel finish.

Advantages

This is an aesthetically pleasing and strong surface. It is also easy to clean and maintain.

Further information

- Resin bound can be overlaid onto existing concrete or asphalt surfaces of suitable construction for the traffic expected.

- Joints of cracks should be broken out to a minimum of 200mm width and filled in with a well compacted concrete base layer (see above diagram).

- We always recommend the use of a geotextile membrane or ground stabilisation membrane - A ground stabilisation membrane helps maintain the stability of the subbase as the membrane prevents stone from migrating into the subsoils.

Important

The specification is based on normal good practice for flexible surfacing and does not absolve the specifier from designing a construction suitable for the expected traffic and ground conditions pertaining on a given site. Areas that may be heavily trafficked by heavy vehicles should have structure layers designed according to DoT requirements.

The thickness of the sub base layer required is dependent on sub grade soil condition.

Disclaimer

The details given in this specification are intended only as a guide. Actual details should be developed by the project designers taking into account the specific circumstances of the intended application. Derbyshire Specialist Aggregates assumes no responsibility for improper reliance upon or misuse of the data herein. Product design and specification are subject to change with further notice.