Product Application: Ready to start

Now you’re ready to start!

The contents of container labelled Part ‘B’ (Hardener) should be added to container labelled Part ‘A’ (Resin) and thoroughly mixed together for approx. 2 minutes using a suitable paddle mixer (Start at a SLOW mixing speed). A cooking timer is useful for to ensure contents are mixed for the correct time.

Warning: When mixing using a drill or paddle mixer, ensure the tub is held firmly between your feet before starting drill. Failure to do this could result in the tub spinning and covering you in resin/hardener mix! – Be especially cautious when mixing in winter as the resin/hardener mix is stiffer and more likely to spin the tub if you do not have a sufficiently firm grip.

Note: Pouring mixed material back into original containers for further mixing will ensure thorough mixing and allow any residue in the containers to cure aiding disposal.

The mixed resin should be poured onto the surface and spread evenly using the SERRATED SQUEEGEE. The serration shape will be reflected in the resin, once these serrations have disappeared, the resin is ready for stone to be broadcast onto it.

Note: If it is windy, the lightweight nature of the resin mix could cause unwanted drift onto other surfaces, to avoid this, place the resin bucket close to the ground to avoid the wind catching the flowing resin.

IMPORTANT NOTE: The resin will start to cure immediately. Tipping all of the resin out of the container and quickly spreading will slow this curing process down; do not leave the resin in the container any longer than is absolutely necessary.

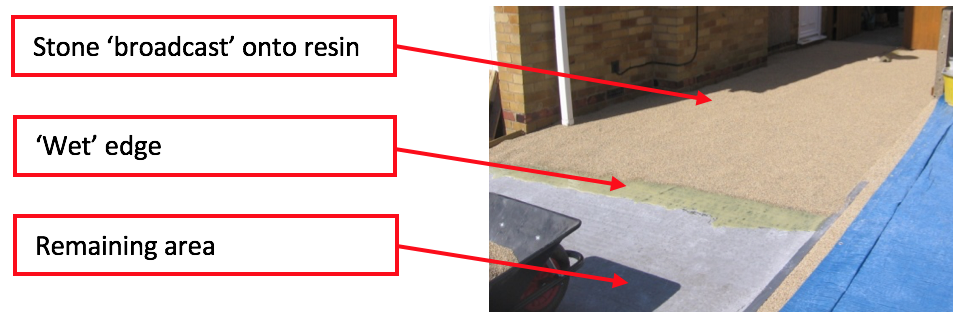

Stone should then be broadcast onto 75% of the surface by hand or a hand shovel, ensuring a WET EDGE is left for application of the next container of resin. See below

The surface should be frequently checked for ‘WET SPOTS’ and topped up with stone.

Continue this process until the surface has been completely covered.